Smart Building - InSCOPE -

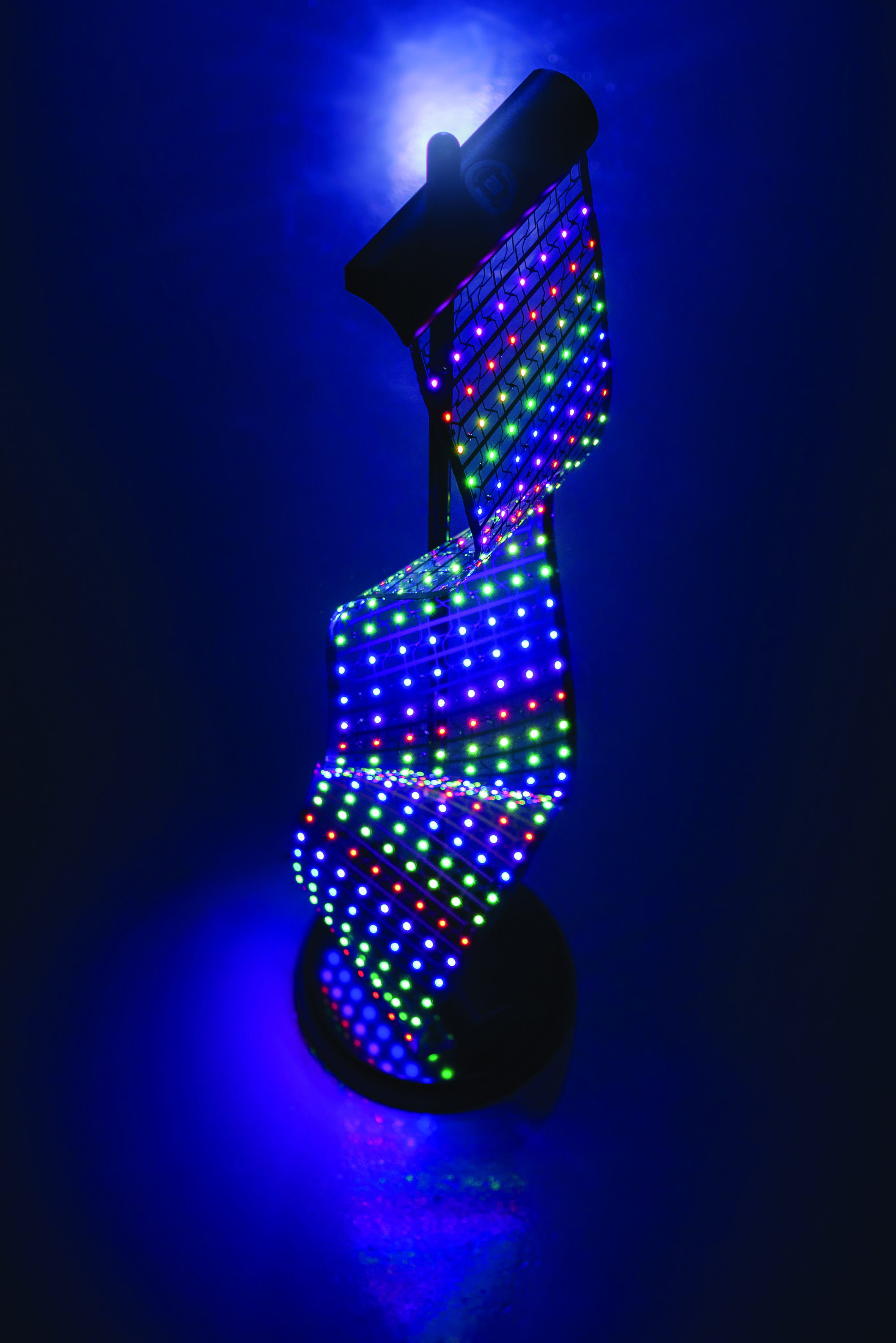

Product idea:Integrated media surfaces enable digital solutions to become part of the spatial experience and dynamic interior designs. InSCOPE bridges the gap between idea and reality producing the following impact:

Our customer

Kone is a manufacturer and provider of reliable, safe and comfortable means that ensure the movement of people in and between buildings. In 2017 they achieved a striking € 8.9 billion in sales and employed more than 55,000 professionals in 60+ countries. As a full partner and end-user of InSCOPE, Kone will be provided with a interactive media surface pilot line for quality approval and commercial release, as well as for assessing its suitability for professional applications.

Aims for pilot line

InSCOPE will demonstrate an interactive media surfaces at low cost in real elevators for Kone. It will be set up step by step in 3 generations:

- Generation 1: set up a panel consisting of a media surface by LED display, including proximity sensors and user interface for interactivity.

- Generation 2: create an interactive media surface in an elevator wall and start with upscaling

- Generation 3: create an interactive media surface in an elevator car

Current achievement

Generation 1 has been successfully completed, including addressable LEDs, transparent proximity sensor and haptic feedback.

The strength of the InSCOPE pilot line service lays in the cooperation between the RTD partners, enabling industrial partners and end-users to request the most advanced demonstrators by selecting from a large pool of manufacturing routes and functionalities spanning over different institutes. This ensures that the end-users can expect an optimal output with respect to costs, reliability and performance. By offering this extensive combination of state-of-the-art processes and state-of-the-art functionalities from all participating partners, InSCOPE is the most comprehensive hybrid TOLAE enabled pilot line service to date related to relevant printing techniques, hybrid integration methods and product integration techniques.

The structure to be developed in InSCOPE should be:

- Thin (<1mm) and light (0.25kg/m2) (currently 11 mm. and 3.5 kg/m2).

- Roll to roll manufactured (200 mm x 2400mm) flexible and transparent display engines with individual controllable RGBW LEDs capable to drive video content.

- People detection in elevator with large area capacitive proximity sensors with 1 m detection distance and capability to recognize different users (adult, child, disabled)

- Integrated, large-area, “Appear-on-demand-in-various-locations“user Interface with capacitive touch sensors, backlighting and haptic feedback (WP3).

- Internal transparency of 94 % for functional foils to enable a) glass wall integration and b) multi-foil stack product architectures

- Unique design freedom in large-area walls with alternating/non-fixed LED pitch/patterns/locations and enabling different functional areas (e.g. areas for 1) User Interface, 2) Infotainment, 3) Animated lighting 4) Tunable general lighting)

- Novel plug&play “mother-foil“with novel foil-to-foil interconnections for power- and signal feeding for functional foils with easy-to-install and easy-up-grade possibility.

- Cost efficiency of the media surfaces by 80 % compared to current reference solutions

Based on Kone key requirements specifications and product architecture for interactive media surface, the functionalities will be applied, design and manufactured on large-area Roll-to-Roll manufactured LED luminaire with packaged LEDs, R2R assembled bare die LEDs, large-area printed capacitive and individually controllable RGB LEDs 8 x 8 matrix display.

- Increasing transparency

- Laminated diffuser layer TBD

- Proximity sensor: Capasitive sensor lay-out TBD

- UI behavior & UX studies

- GUI studies: UI locations, Haptic feedback validation, UI appearance

- UX studies at Amos Rex Elevator car