Users

The main direct beneficiaries of the InSCOPE open access pilot line are SMEs which already have a (hybrid) printed electronics demonstrator but do not have the necessary manufacturing capacity to transform the existing demonstrator into production prototype for volume manufacturing.

Typical request of SMEs which qualify for InSCOPE pilot line support are:

- I would like to produce samples on large quantity and at good quality

- I have a product demo and want to do clinical trials

- I want to show the potential of my products to a large set of potential customers

- I have a large product

- I want to validate “state of the art” production methods

- I want to validate technology close to implementation.

Services

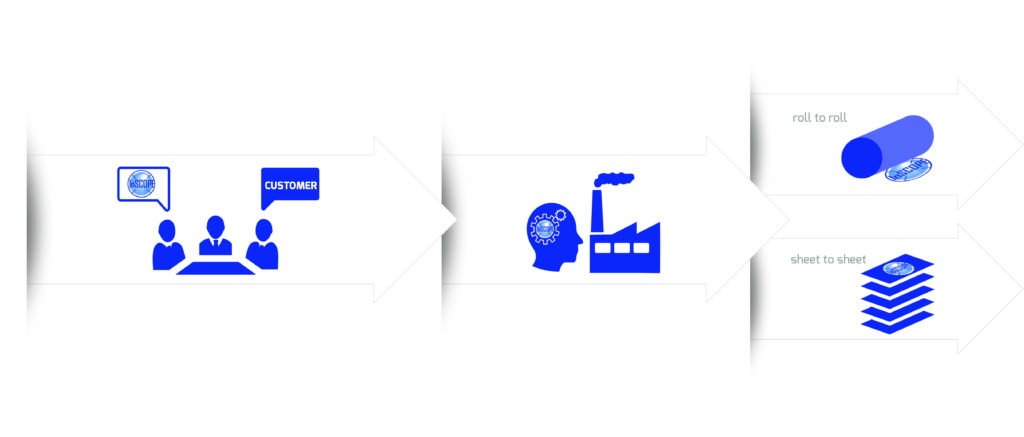

Three types of services are available by the InSCOPE pilot line:

1. OPTIMAL PRODUCT DESIGN AND PRODUCTION PROCESS CHOICE

Users of the pilot line can transform their existing (hybrid) Printed electronics demonstrator into a production prototypes ready for volume manufacturing.

2. BENCHMARK PRODUCTION PROCESS ON SOTA EQUIPMENT

The InSCOPE consortium provides an overview and test the available production process that are state of the art in printed electronics. Proposals for optimal production within InSCOPE pilot line is offered to our customers.

3. MAKES RELIABLE PRODUCTS IN LARGE NUMBER FOR EVALUATION

End-users of the pilot line service will eventually require sampling at industrial relevant scale. InSCOPE samplings are reliable and non-fault to pass such tests.

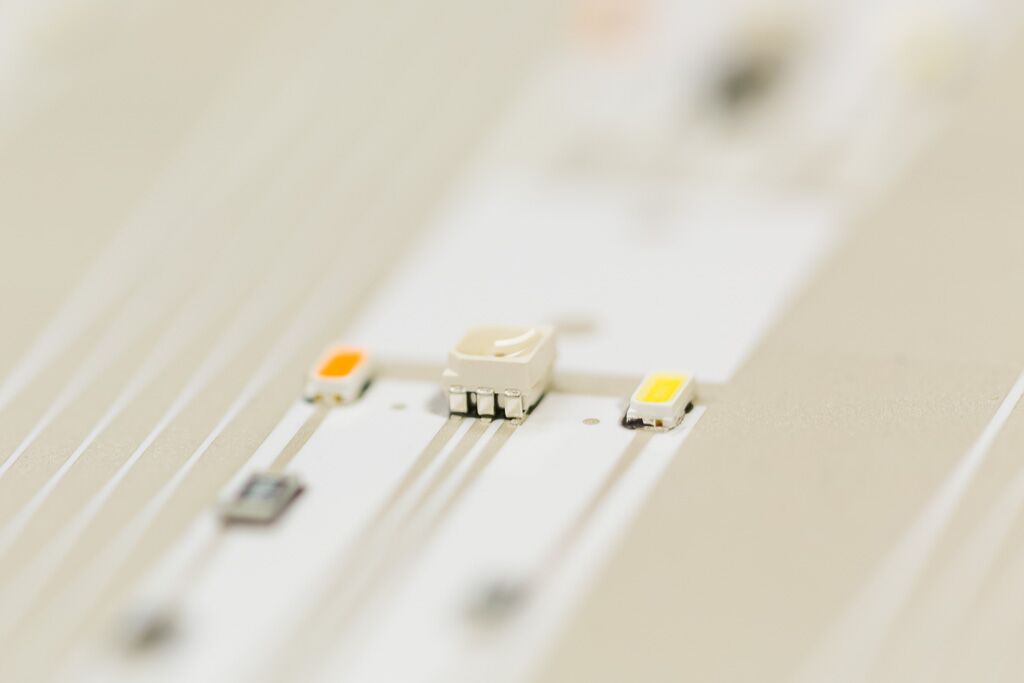

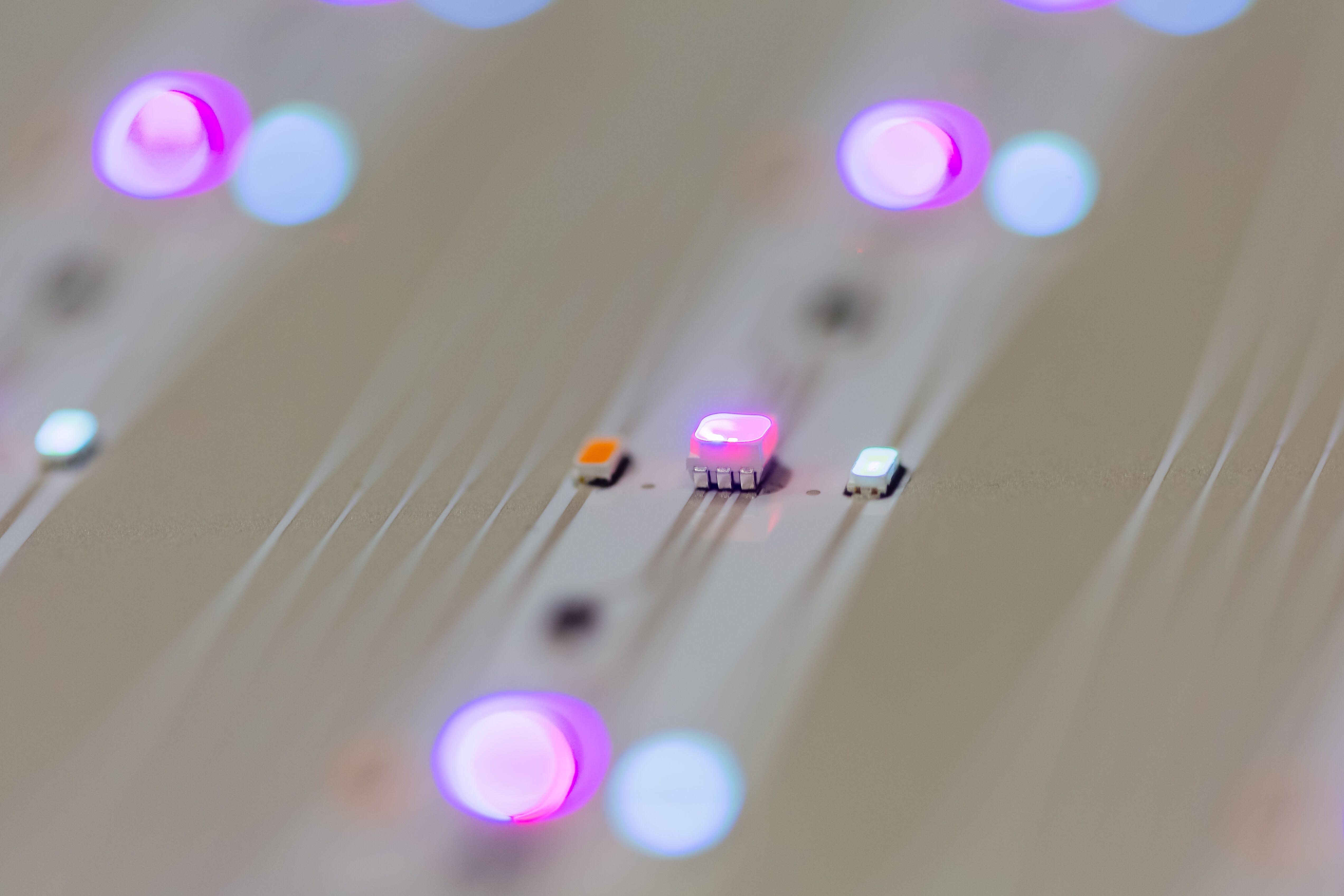

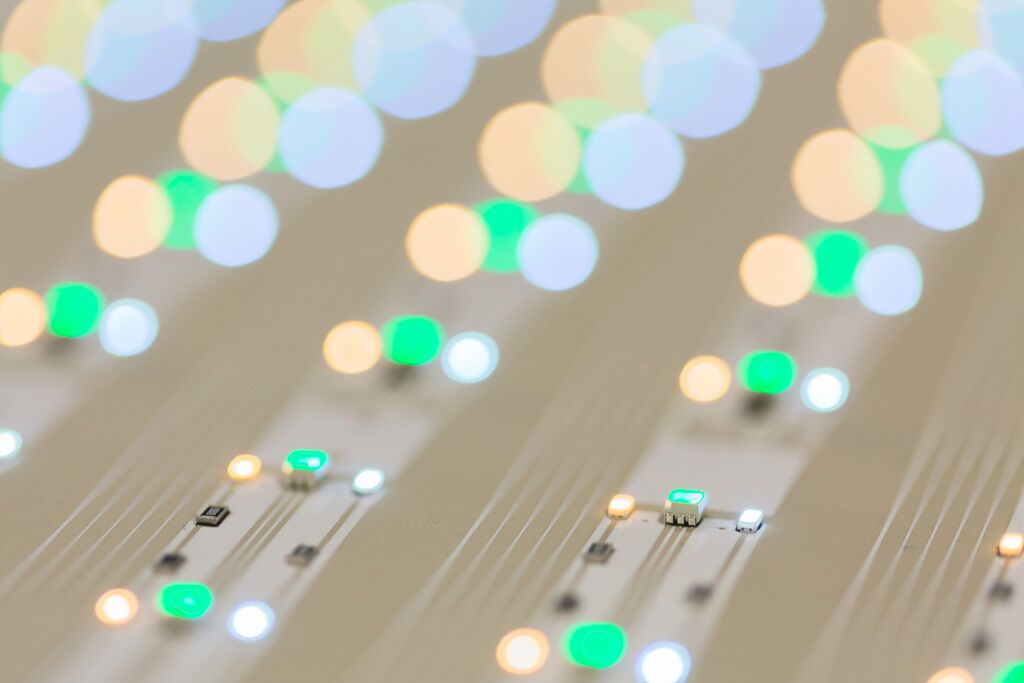

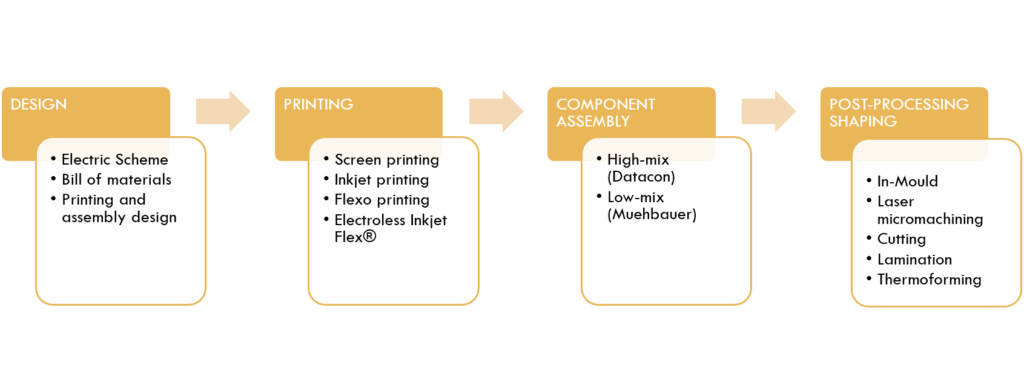

The InSCOPE Pilot line is made up of three primary units: printing, component assembly and post –processing which are which are complemented by design / support for required driving electronics of a given functionality.

Benefits

INSCOPE PILOT LINE WILL HELP YOU REDESIGN YOUR EXISTING PRODUCTS WITH NEW FEATURES AND / OR REDUCE PRODUCT COSTS OR FORM FACTOR TAKING ADVANTAGE OF HYBRID TOLAE POSSIBILITIES.

The advantages of hybrid TOLAE, owing to the printed and foil based aspect, are its flexibility and cost effective production method over large area. In addition it provides an excellent base for realizing new types of large area substrates that may even be shaped into three-dimensional products. The hybrid integration step of the H-TOLAE manufacturing process enables:

- SMART FEATURES,

- SIMPLE CIRCUIT

- STATE-OF-THE-ART PERFORMANCE.

Early adopters of new technologies will progress significantly faster on the product development, by having functional prototypes ready for customer satisfaction or reliability testing and for faster innovation cycles before the actual large volume production.

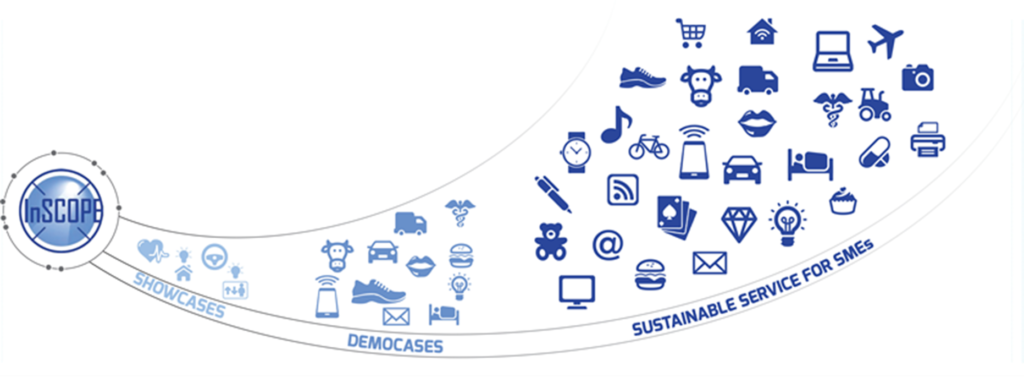

Sectors

The printed electronics technology is especially suited for market sectors that require high standards and quality products:

- Combined with unique (smart) functionalities

- Flexibility and even stretchability

- Available on large areas/quantities

Examples of target sectors:

- Automotive

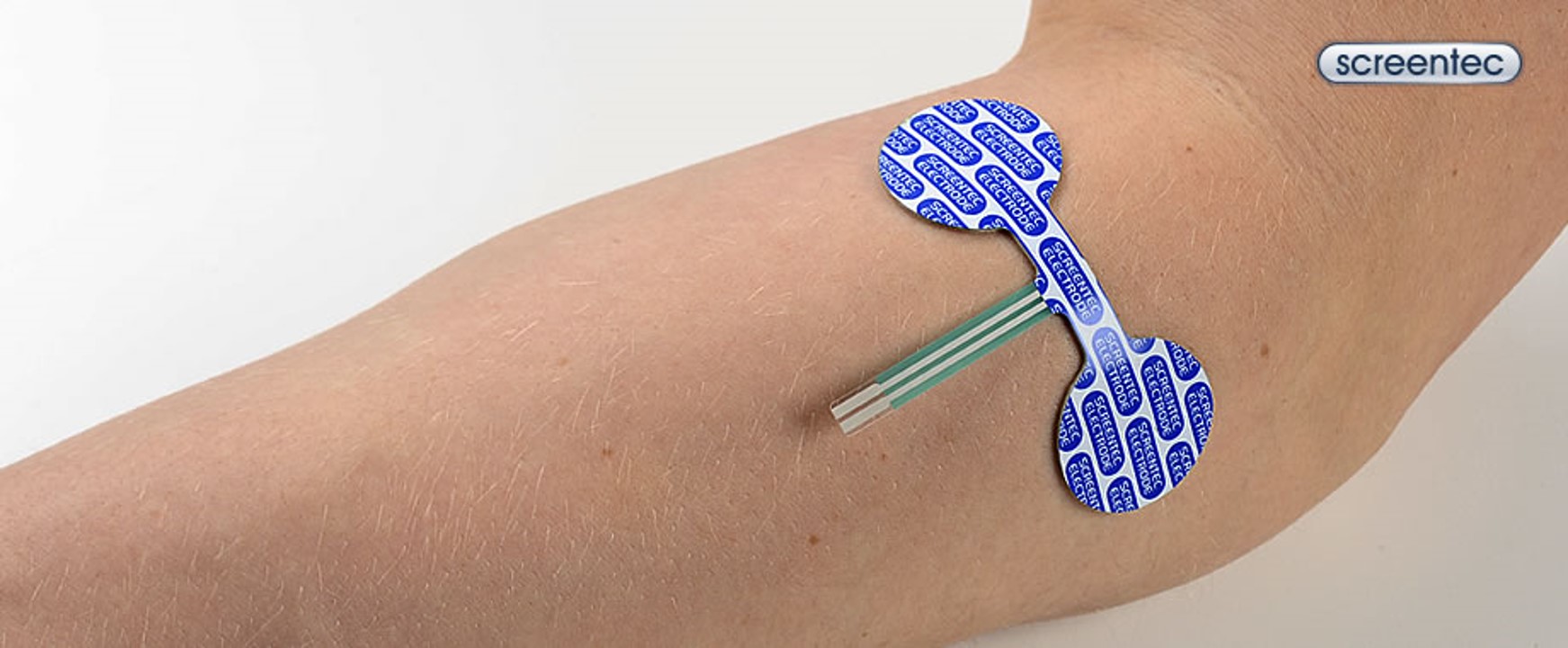

- Health

- Smart packaging

- Smart building sectors

- Textile

How

Contact our project coordinator to learn more and discuss your possibilities with the InSCOPE pilot line

Corne Rentrop

TNO – HOLST CENTRE

Eindhoven, Netherlands

Email: corne.rentrop@tno.nl